As electric mobility accelerates worldwide, charging station operators face fierce competition. Minimizing OPEX (operational expenditure) through a Low Operation Cost Charging Pile strategy is the cornerstone of sustainable profit. Below, we dive deep into the four pillars of OPEX, illustrate SRE Power’s factory-direct solutions, and share actionable tactics to cut costs by over 30%.

1. The Four Pillars of OPEX: Pinpointing Your Biggest Cost Drivers

1.1 Equipment Purchase & Installation

Factory-Direct Pricing: SRE Power designs and manufactures in Shenzhen, Dongguan, and Malaysia, offering 12 kW AC dual‑gun and wall‑mounted chargers at factory-direct rates. Cutting out middlemen saves 10–15% on unit costs for your Low Operation Cost Charging Pile deployment.

Site Preparation Costs: Civil works and grid hookups vary by location. Bulk procurement and local contracting partnerships can trim these expenses further, making your EV charger’s total cost of ownership more economical.

1.2 Electricity Costs

Time-of-Use Optimization: SRE Power’s cloud-based management platform automates charging schedules to avoid peak tariffs, slashing energy bills by 20%+—a key tactic in reducing EV station operating expense.

PV + ESS Integration: Where rooftop solar is available, integrate photovoltaic panels and energy storage to offset grid consumption and deliver a truly cost-effective charging station operation.

1.3 Maintenance & Service Fees

Predictive Maintenance: Built‑in OTA upgrades and self‑diagnosis detect issues before failure. Early alerts cut emergency repair events by half, driving down ongoing OPEX for every charging pile.

Cloud Service Packages: Instead of per-device fees, SRE Power offers annual subscriptions under $50 per charger, covering data hosting, remote support, and software updates—further lowering your economical EV charger OPEX.

1.4 Value‑Added Operations

Advertising Revenue: Embed third‑party ads on charging kiosk screens or housings, sharing ad revenue with partners. This transforms each charger into a revenue-generating asset.

Subscription & App Services: Launch membership plans, top‑up bonuses, and premium mobile‑app features to create recurring income streams and enhance your Low Operation Cost Charging Pile business model.

2. The “Golden Triangle” of OPEX Reduction

2.1 Factory-Direct + Modular Design

Right‑Sized Power Modules: Choose from 12 kW, 20 kW, or 120 kW units to match real demand—no over‑building and no wasted CAPEX.

Scalable Production: Multiple campuses and lean manufacturing lower fixed overhead, passing savings onto you and reinforcing your low-cost charging pile strategy.

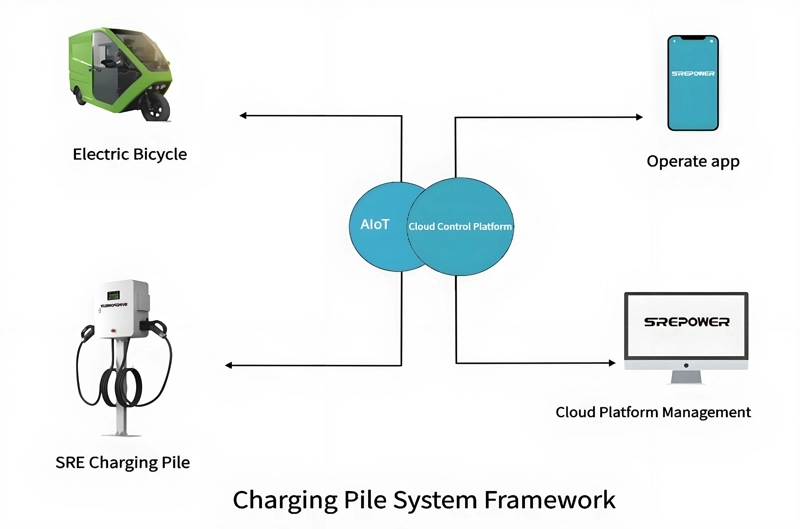

2.2 Intelligent Cloud Management

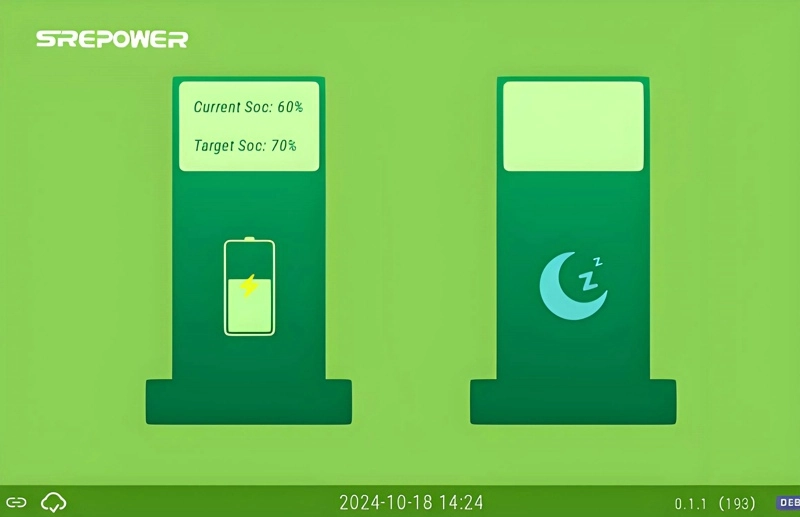

All‑in‑One Dashboard: Real‑time monitoring, OTA firmware updates, and instant fault alerts reduce on‑site visits—key for cutting charging station operating expense.

Automated Demand Response: The system shifts non‑urgent charging to off‑peak hours, maximizing tariff arbitrage and making your charging solution more cost-effective.

2.3 Policy & Financing Support

Subsidy Assistance: SRE Power provides all certification documents needed to apply for local, state, or national EV infrastructure grants and tax credits—helping you secure incentives that further lower OPEX.

Low‑Interest Loans: Partner banks offer preferential financing terms, shrinking both upfront and financing costs of your electric vehicle charging station.

3.SRE Power 120/160 kW Fast Charger Highlights

As a leading charger manufacturer, SRE Power’s 120/160 kW Fast EV Charger is tailored for four‑wheel EVs and offers:

3.1 High‑Performance Output

120/160 kW Power: Delivers up to 200 km range in just 20–30 minutes.

Dual‑Gun Simultaneous Charging: Charge two vehicles at once, boosting station throughput.

3.2 Smart Connectivity & Management

Cloud‑Based Platform: Real‑time data collection via OCPP, with a visual dashboard for operators.

NFC & App Activation: Users start charging via NFC card or mobile scan.

Over‑The‑Air (OTA) Updates: 2G/4G connectivity ensures seamless firmware upgrades and remote control.

3.3 Comprehensive Safety Protections

IP54‑Rated Waterproofing & Rust Resistance: Reliable performance in outdoor environments.

Multi‑Layer Alarms: Overcurrent, overvoltage, overtemperature, and ground‑fault detection with SMS alerts.

Battery Intelligence: Auto‑recognition of battery specs to optimize charging profile.

3.4 Key Specifications

-

Output Voltage

-

DC200V~1000V

-

Output Current

-

400A OR 200A*2(Max)

-

Display

-

7”TFT Color touch screen

-

Operating Temperature

-

-20℃~60℃

-

Communication Mode

-

CAN , Wireless Communication

-

Communication Interface

-

Ethernet、2G/3G/4G(Optional)

-

Billing Interface

-

RFID , IC , CPU

4.Real‑World Case Studies: 30%+ OPEX Savings

Mixed‑Use Urban Complex: Deployed 20×12 kW column chargers plus a 200 kW solar+storage array. Combining time‑of‑use scheduling and onsite generation cut annual energy spending by $18,000 and trimmed maintenance costs by 35%, illustrating how a Low Operation Cost Charging Pile can outperform standard station models.

Retail Parking Hub: Installed dual‑gun fast chargers and incorporated ad screens. Peak turnover charging plus ad revenue increased utilization to 18%, shortening the payback period to just 2.5 years—showcasing how to maximize reduce EV station operating expense through value‑added services.

5.Five‑Step Selection Guide: Turning “Low Cost”into Reality

Five‑Step Selection Guide: Turning “Low Cost” into Reality

Demand Assessment: Accurately model daily peak load and user profiles—avoid over‑sizing and unnecessary CAPEX.

Vendor Comparison: Benchmark multiple suppliers on modular pricing and lifecycle services; leverage SRE Power’s direct‑factory advantage to secure the most economical EV charger OPEX.

ROI Modeling: Build a 3–5 year cash‑flow projection factoring CAPEX, OPEX, subsidies, and residual value.

Factory Audit: Tour SRE Power’s manufacturing centers and test labs to validate quality control and production capacity.

Continuous Improvement: Use cloud analytics to review utilization trends, tweak charging schedules, and optimize maintenance intervals—ensuring your charging pile remains a low-operation-cost champion.

6.FAQs

Q: How do I calculate total OPEX for my site?

A: Sum equipment amortization, energy bills (at average tariff rates), scheduled maintenance, cloud service fees, and any insurance or compliance costs.

Q: Can I apply for government subsidies with SRE Power’s support?

A: Yes. We supply all required technical certifications, CE/UL reports, and application guidance for major markets.

Q: What remote‑monitoring features come standard?

A: Real‑time status dashboards, customizable alerts, OTA firmware updates, and usage analytics reports.

7.Next Steps: Partner for Low‑Cost, High‑Efficiency Charging

Lowering OPEX is not a one‑off cut; it demands a holistic approach across equipment, energy management, maintenance, and value‑added services. With SRE Power’s factory‑direct pricing, modular product line, and smart cloud platform, you can drive OPEX down by 30% or more—while boosting reliability and customer satisfaction.

Guangdong SRE Technology Co., Ltd. | Global EV Charging Solutions Manufacturer

Website: https://www.srepowerne.com/

Email: info@srepowerne.com

WhatsApp Contact

WhatsApp Contact